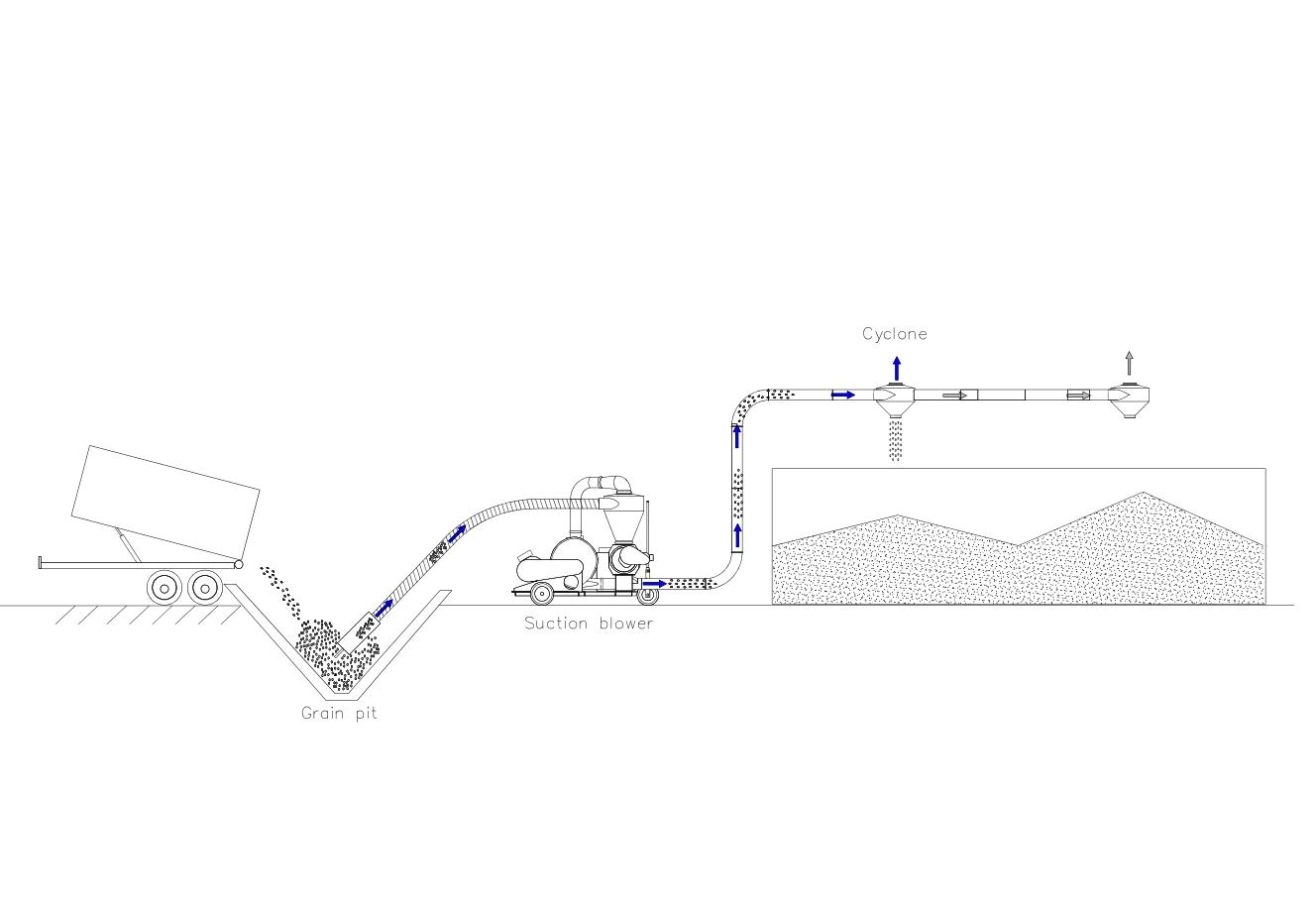

Filling and Emptying System for On-Floor Storage

A pneumatic conveying system for filling of on-floor storage can easily be installed everywhere.

Filling and Emptying System for On-Floor Storage

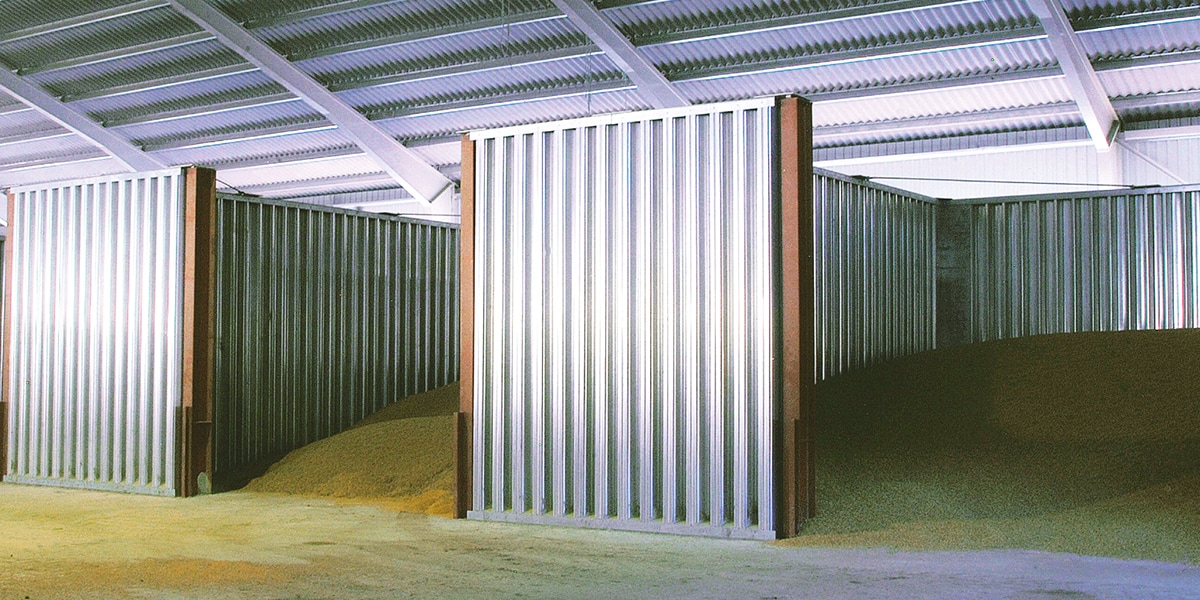

A pneumatic conveying system for filling of on-floor storage can easily be installed everywhere. Such a suction/blowing system is very easy to install with hardly any demands to the building construction itself. It is merely a question of finding space for installation of the conveying pipe.

The grain is easily vacuumed up from the floor, from a small hopper, or by suction directly from a trailer. The grain is then transferred through a pipe system. Diverters can be installed in the pipe system in such a way that the grain can be directed to one of several delivery points of your choice. By filling the storage in several points, you reduce the work related to levelling the grain. It also allows for better filling of the storage in buildings of low height.

The blower is placed with convenient accessibility at floor level. Moreover, none of the more technically complicated equipment is placed in places without easy access.

Businesses We Serve

Whether your business deals in organic or conventional farming, Kongskilde has a solution designed to optimize your processes and production.

Download Resources

Download the latest Kongskilde PDF documents, brochures, data sheets, manuals, and more.

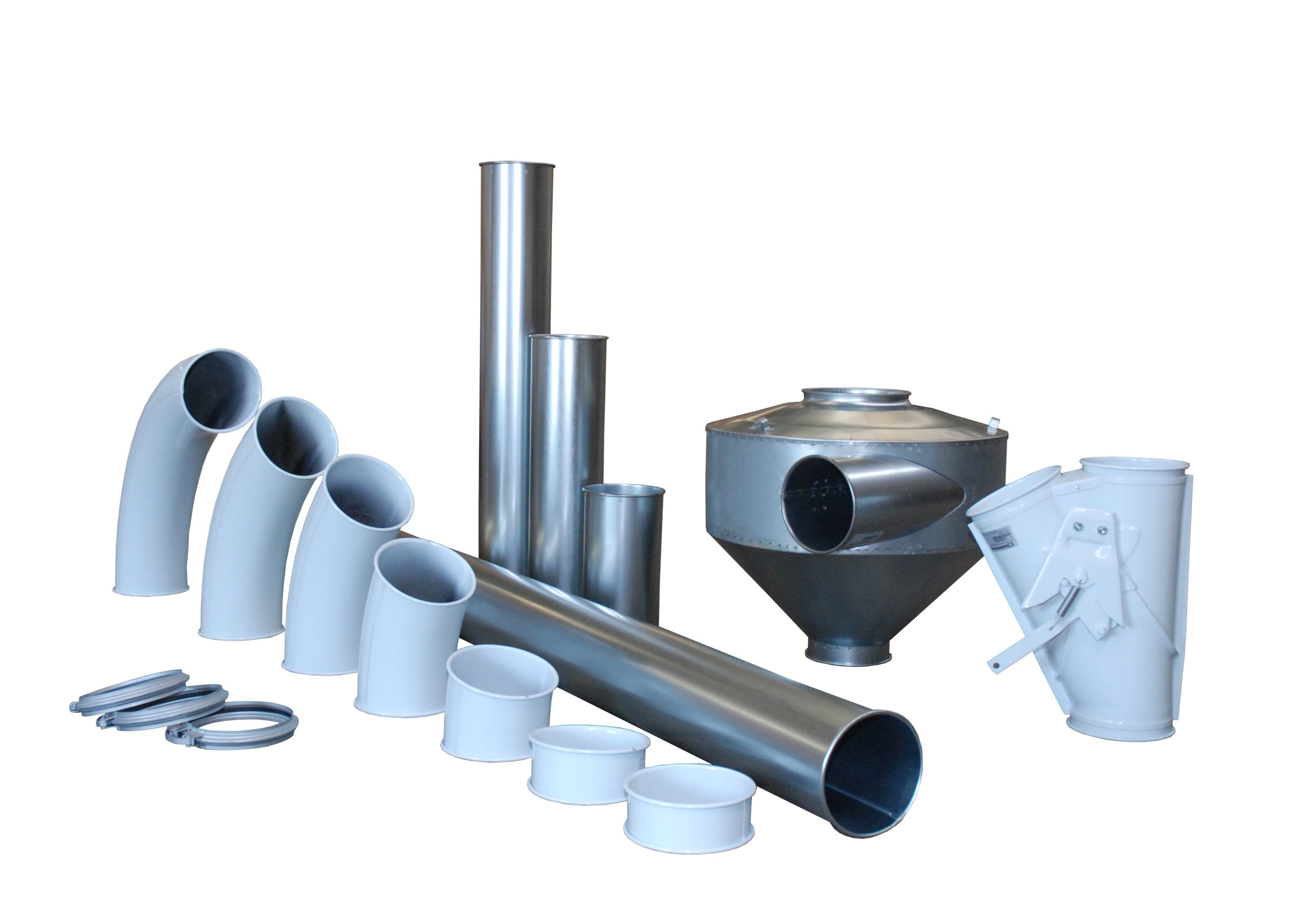

Related Products

Designed for maximum flexibility, reliability, and quality, Kongskilde’s portfolio of complementary products offers additional customization for our world-class pneumatic systems.