Mechanical Conveyors

Chain Conveyors – KCC and KCA

Kongskilde KCC and KCA chain conveyors are ideal for horizontal conveying of grain and granular materials.

Kongskilde KCA chain conveyors meet the demand for a conveyor able to convey grain and granular materials both horizontally and with an inclination to give a vertical lift. The KCA can be delivered with 30 or 45 degree angle sections for installation in grain intake pits. Max. inclination allowed for the KCA conveyor in any configuration is 45 degrees.

Both the KCC and the KCA chain conveyors are produced in heavy-duty galvanized execution and are designed in a modular construction, making them easy to assemble and install.

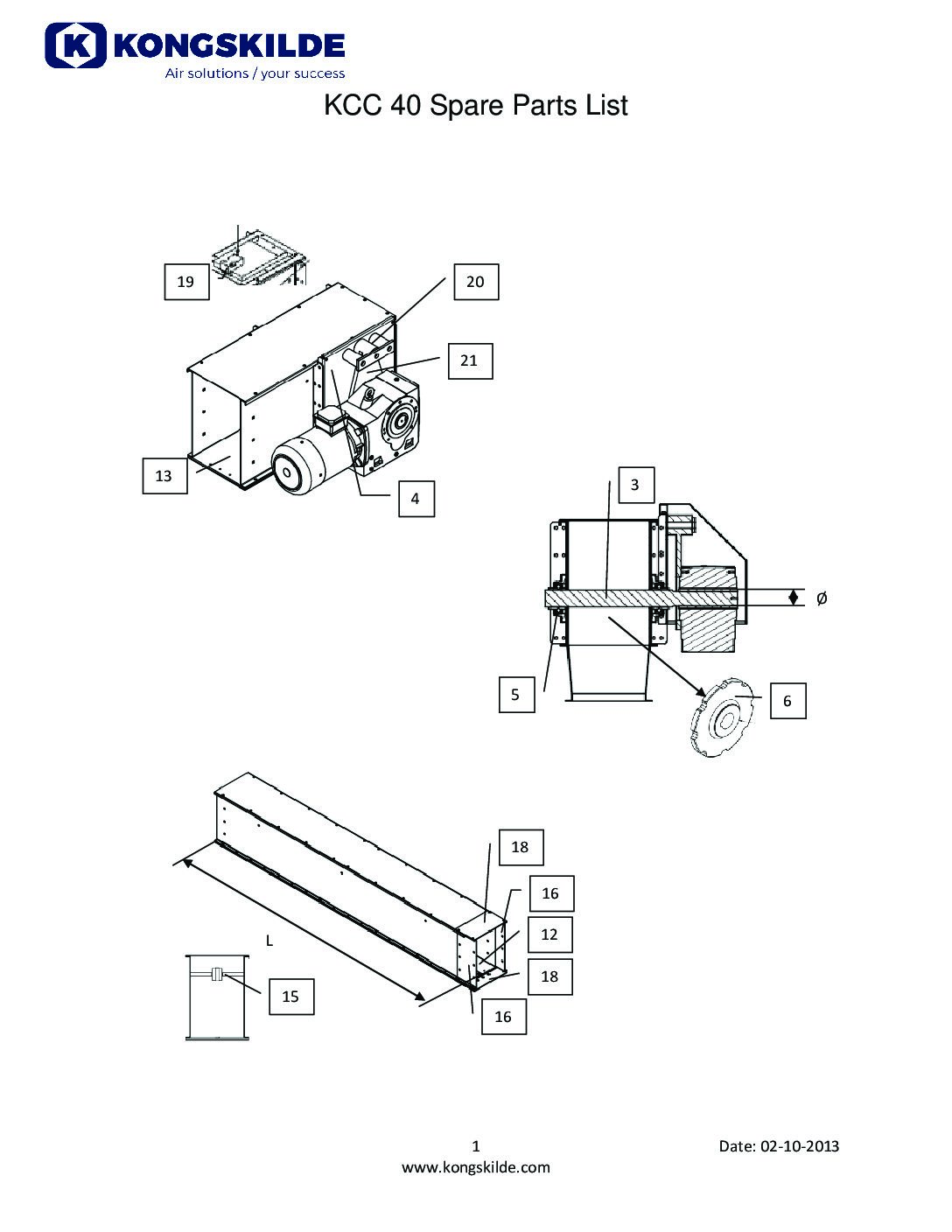

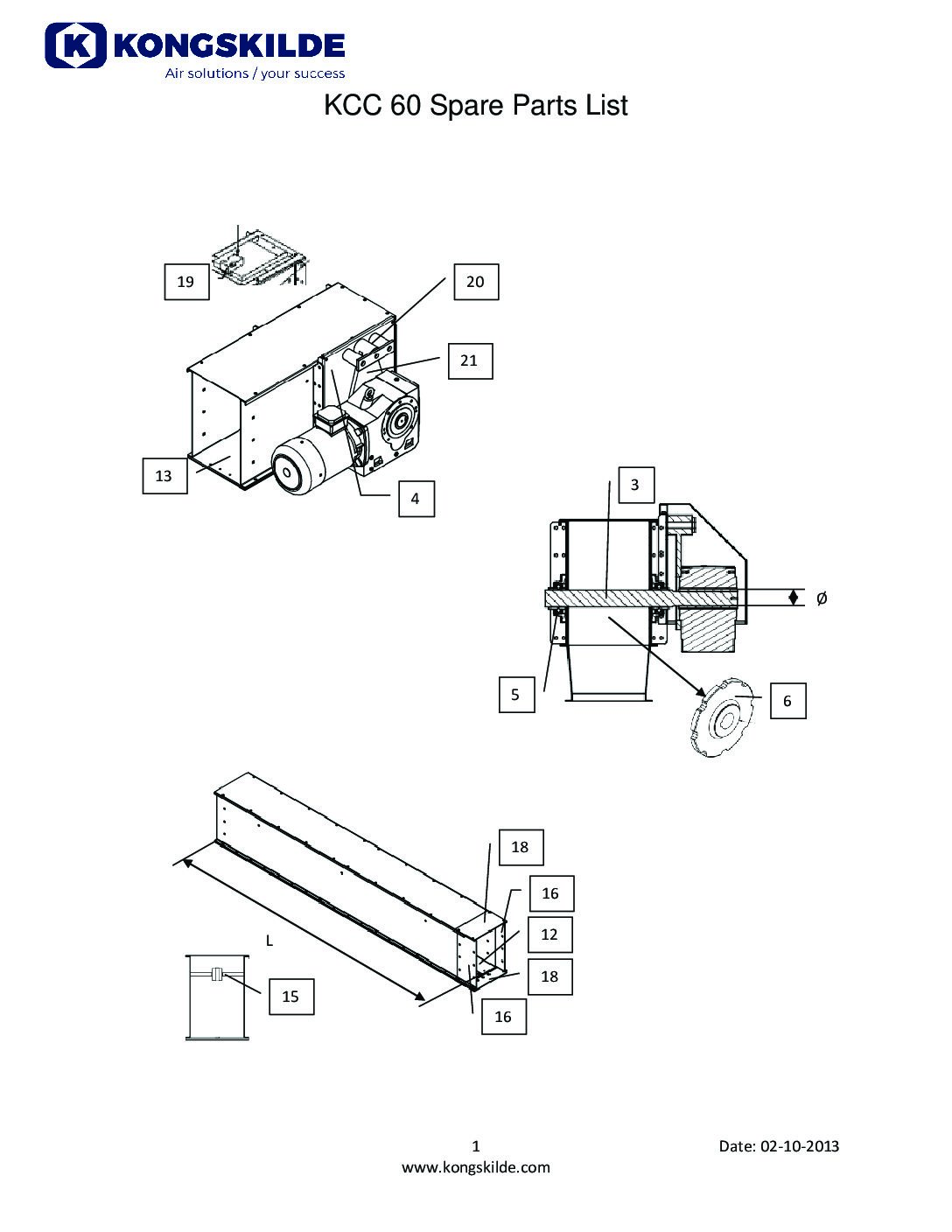

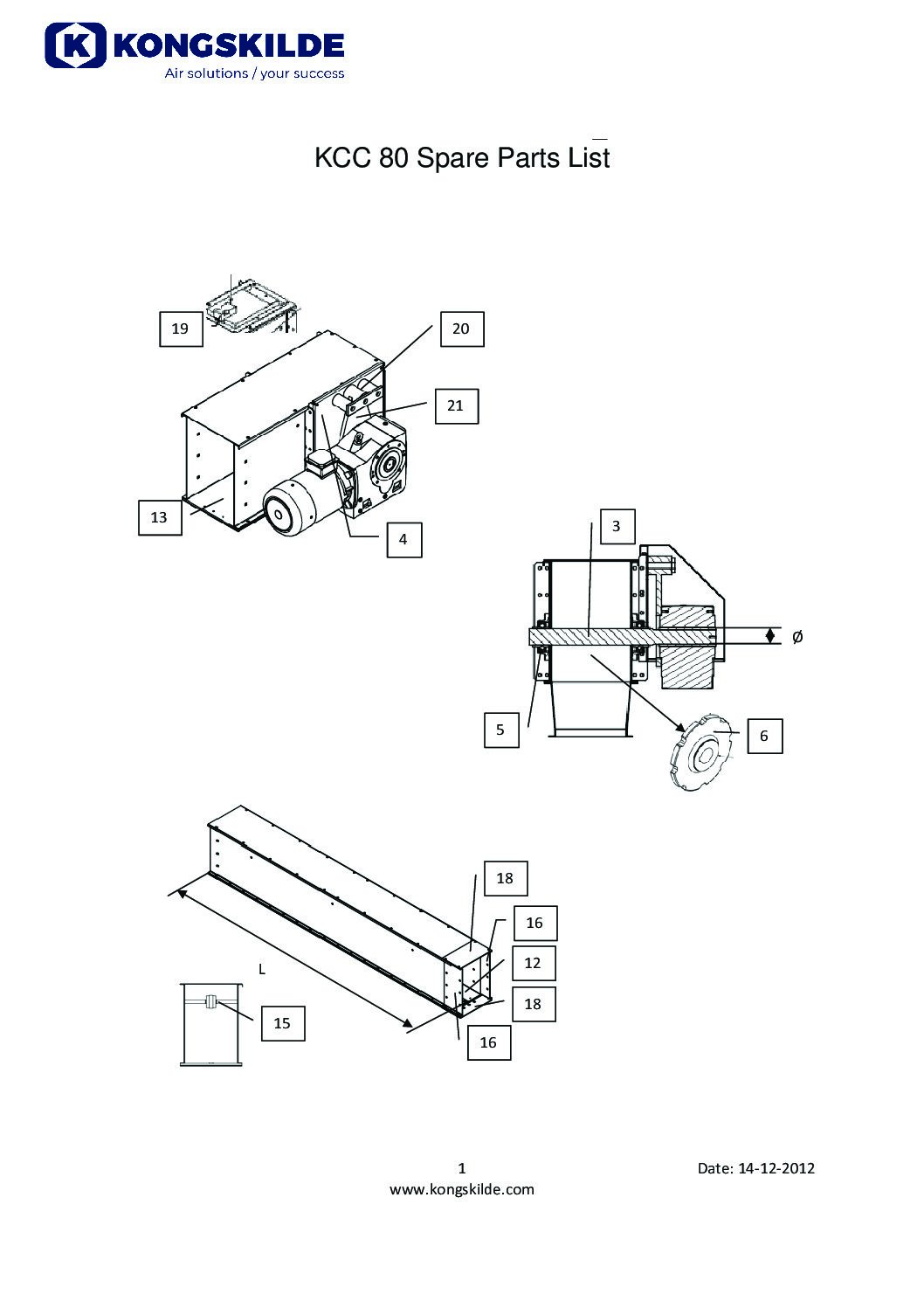

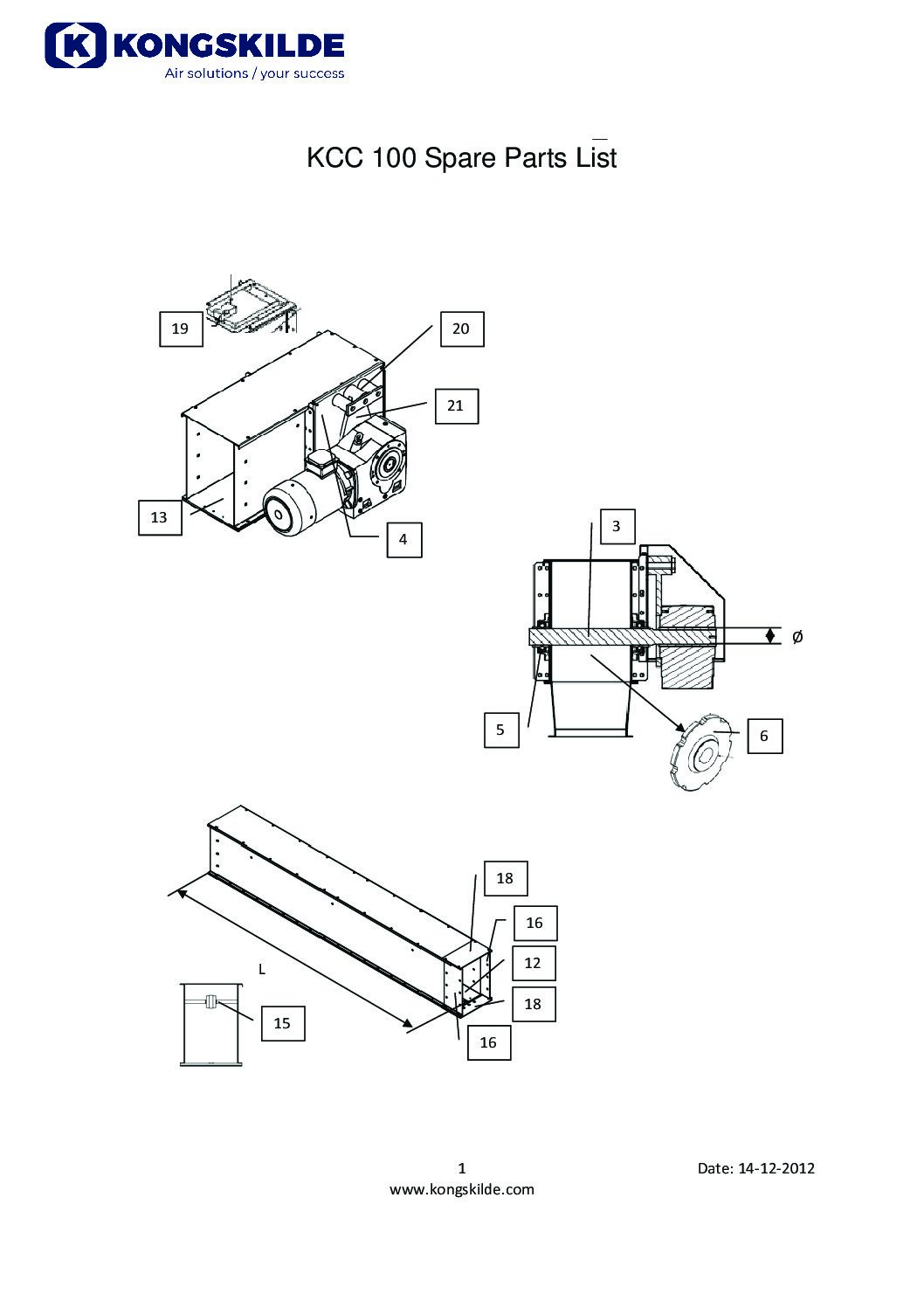

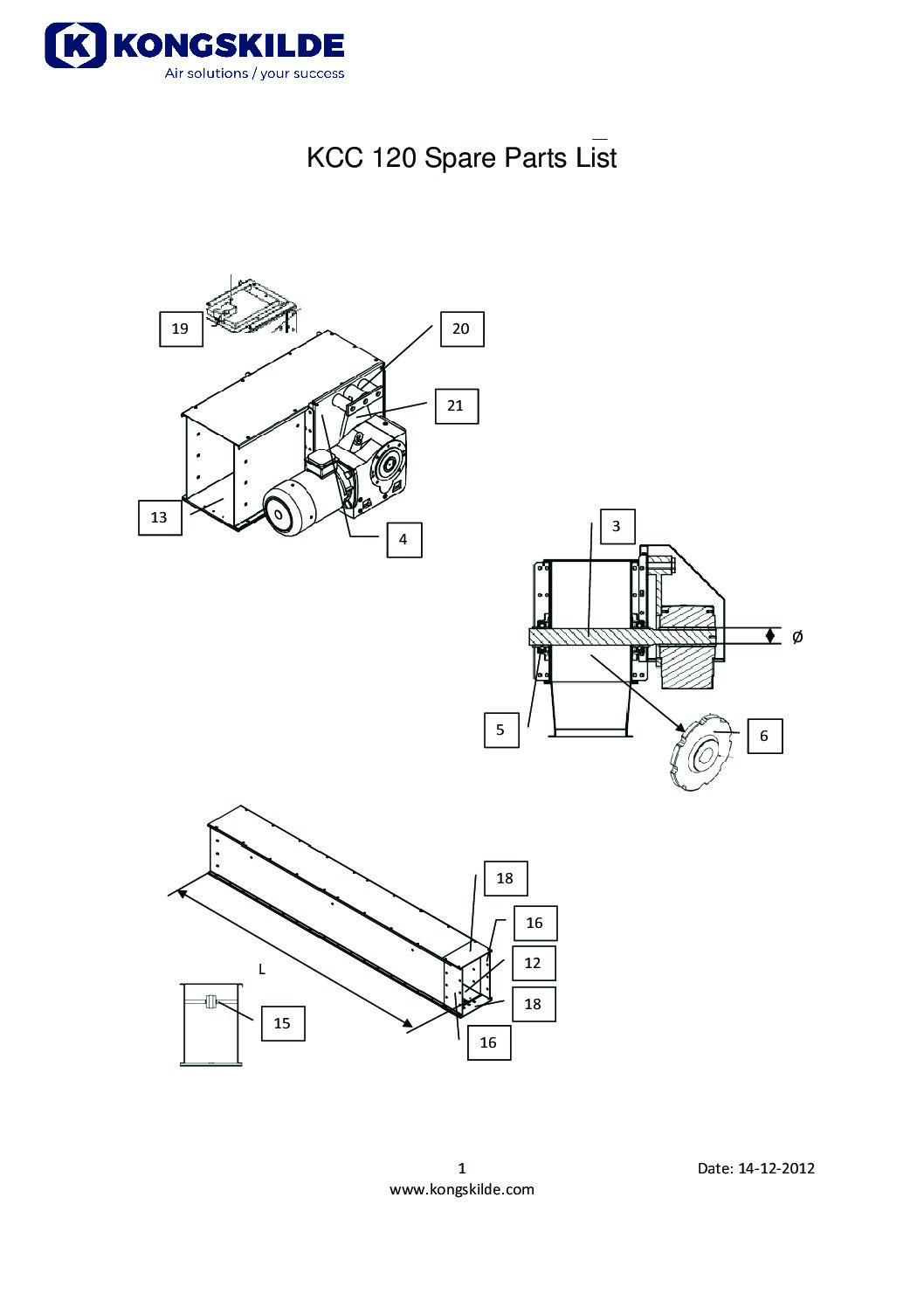

KCC Chain Conveyors

KCC chain conveyors are used for horizontal conveying of grain and can be built in lengths of up to 50 m. Conveying capacities of up to 120 t/h (750 kg/m3).

Benefits

- Quick and easy assembly for different conveying distances using standard modular system of extensions

- All modules are made from galvanized steel

- Suitable for outdoor installation

- The conveyor is supplied with a 10 mm PEHD-reinforced base

- High efficiency bevel gear motor with minimal space requirements

- Overflow flap with switch on drive unit

- Cleaning buckets with carriers every approx. 2m chain

- Extensions with side inlet for installation in grain pit

Accessories

- Intermediate outlet, manual or electric operation

- Inlet with capacity control

- Wide range of inlets to fit different standard pipe diameters

- Capacity control for chain conveyors with side inlets

- Rain cover for bevel gear motor

- Cleaning brush on intermediate outlet to avoid overflow

KCA Chain Conveyors

KCA chain conveyors are ideal for conveying of grain when inclined conveying up to 45 degrees is needed. Capacities from 60 to 120 t/h.

Benefits

- Wide range of standard extension modules

- Galvanized external conveyor surfaces

- Suitable for outdoor installation

- Bevel gear motor means high efficiency and easy installation

- Low noise levels thanks to PEHD carriers on the conveyor chain

- Overall length up to 50 m, depending on layout and capacity

- Extensions with side inlet for horizontal installation in grain pit

Accessories

- 30° and 45° angle sections from horizontal to inclined and from inclined to horizontal conveying

- Drive unit with chain tensioner

- Range of standard inlets and outlets

- Manual or motorized intermediate outlet

- Transmission for bucket elevator intakes

- Rain cover for bevel gear motor

- Blockage cut-out switch at drive and return end

Downloads

Download brochures, data sheets, manuals, and spare parts lists for the KCC and KCA Chain Conveyors.

Brochures and Data Sheets

Manuals

Spare Parts

KCC and KCA Chain Conveyor Applications

Kongskilde KCC chain conveyors are an ideal solution for horizontal conveying of grain and granular materials.